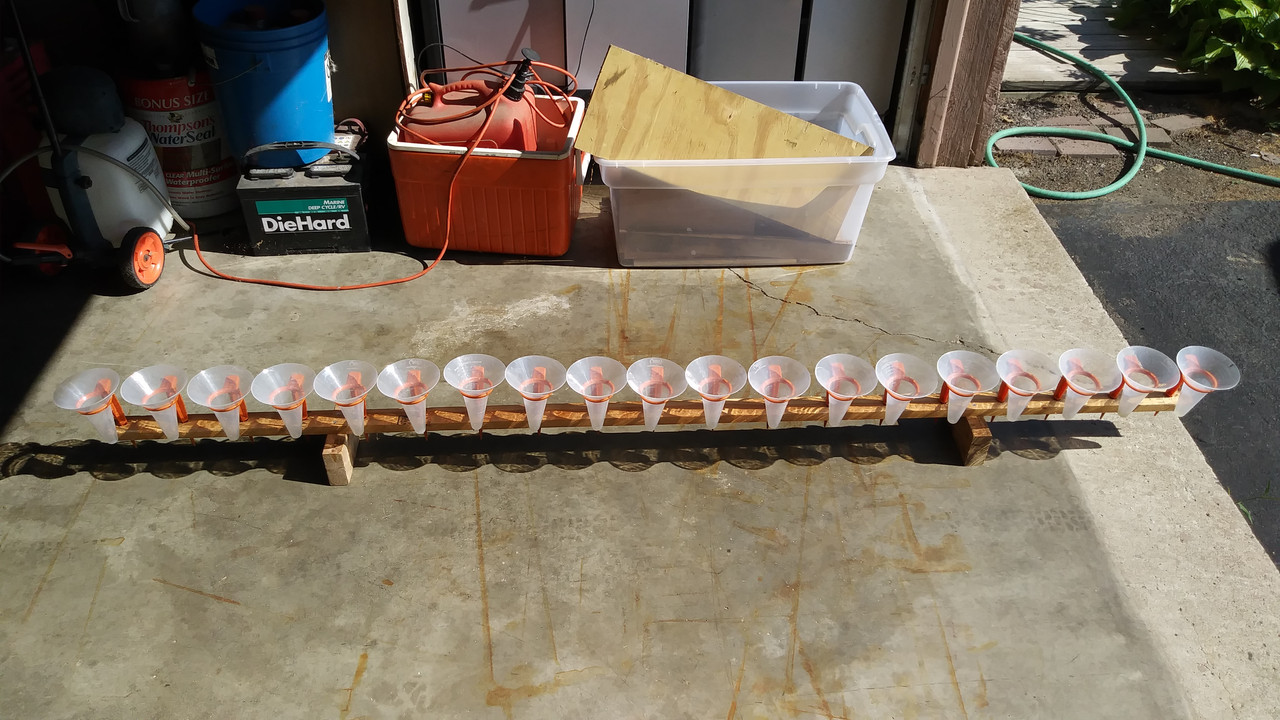

Nice setup

@TommyTester!

I am surprised to see a dip and rise at each end, I would have expected a standard normal distribution shape.

I wonder if the distribution you recorded is a function of the catch cup shape. There are two reasons I think this may be the case:

1. I would expect the middle of the application to be more narrow in depth (less dispersion) than the ends and the ends more misty (particles traveling a longer distance).

2. The angle at which the water droplets hit the cups may impact collection within the cups. The water droplets are not falling straight down, like rain. Maybe the particles are hitting the cup at the ridge and falling below.

Might get a different picture if your collection apparatus were more continuous with more depth (front to back). I attached a photo and suggestion at the end of this thread.

If the width of application is 42" while the fan tip is 21" off the ground that implies a 90 degree angled tip - is that what you were using?

A few more questions about the last graph in the you YouTube video:

What does the note "100% overlap" mean? Edge of current lane alingned with center of prior lane?

What is the x axis? Total width of 2 lanes combined?

What do the colored lines represent? Nozzle height, lane width, or something else?

Really cool test. Can't wait to see more!! :thumbsup:

Suggestion: just thinking out loud here but what about taking 96 cube ice cube trays (or something similar) and cutting them into 3x4 or 6x4 sections. Each section would replace a collection cup. Each tray would be placed immediately adjacent to the next so there would be no gaps. To measure volume of water, pickup a tray and dump it in a collection cup or other measuring cup and this would give you a good picture of how much product is applied in each band/ice cube tray section.

I wonder if 4 cubes deep would be enough to catch the mist at either end accurately? Six deep might be better. I understand if you don't feel the increase in accuracy warrants the increase in work but I do wonder if the end cups are impacted by the 2 considerations above.